Fiber Optic Extrusion / Upjacketing Services

PrecisionOT/Opticonx provides comprehensive extrusion and upjacketing services for custom fiber optic solutions, supporting virtually any fiber type and guiding products from concept and design through manufacturing with capabilities including buffering, cabling, and jacketing. With flexible production, short-run support, and extensive material and construction options, Opticonx delivers custom-designed fiber cables tailored to exact application requirements using in-house or customer-supplied fiber.

Description

Key Features

Applications

Documents

Description

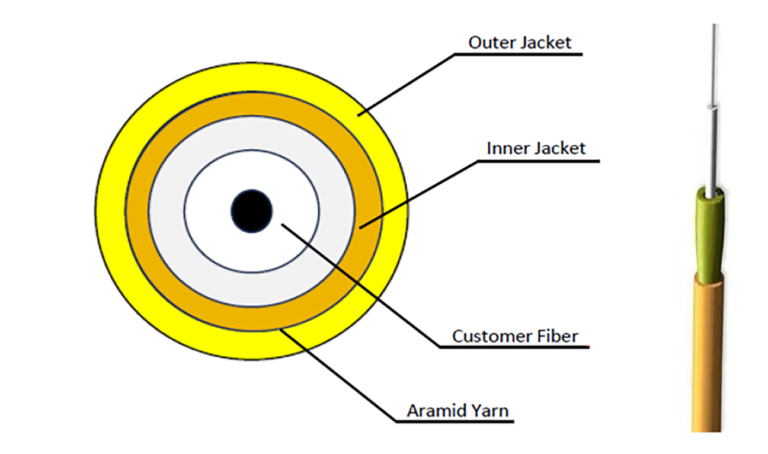

Precision OT/Opticonx offers comprehensive Extrusion and Upjacketing Services for custom fiber solutions. We can work with virtually any fiber type to deliver the solution you require. Our engineering team specializes in taking a product from concept to design and then through manufacturing. Capabilities include buffering, cabling, and jacketing a variety of fibers.

With extensive manufacturing experience and flexibility, Precision OT/Opticonx can custom design and manufacture fiber optic cables to specific requirements and specifications unique to your application and intended use. This can be done with in-house fibers or customer-supplied fibers. Short runs are welcome, and design consultation is available.

Options include:

- Customer supplied fiber

- Fiber counts from 1 – 72

- Fiber types: OM1 – OM5 multi-mode, OS2 singlemode and polarization maintaining

- Tight-buffered, loose-tube, flat & rollable ribbon and other fiber types

- UL-listed ONFR and OFNP, LSZH, Indoor/Outdoor jackets

- Hybrid multi-mode / singlemode constructions

- Custom coloring and jacket printing

- Buffering optical fiber

- Jacketing optical fiber

- Cabling optical fiber

- Coloring optical fiber

- Furcation tubing

- Ability to process a wide range of materials

- Standard and custom tooling

- Short run and production quantities

- Standard and custom colors

- Custom print legends and Labeling

- PVDF (KYNAR FLEX® 2950-05 Standard Mod, KYNAR FLEX® 2850-00 High Mod)

- TPE (Hytrel® 6356), also 5556, 7246 or 8238

- LDPE (Polyethylene), Borstar® LE8706

- Nylon

- FR-PVC (Flame-retardant Polyvinyl Chloride)

- Plenum PVC

- LSZH Polyolefin (HFFR TPO) MtegrityPlusTM 2545

- LSZH Polyurethane (HFFR TPU) HFC 9140

- CPE

- Polypropylene Borealis BC545MO

- PVDF (KYNAR FLEX® 2950-05 Standard Mod, KYNAR FLEX® 2850-00 High Mod)

- TPE (Hytrel® 6356)

- LDPE (Polyethylene), Borstar® LE8706

- Nylon

- Custom configuration

- Private labeling

- Custom labeling

- Custom packaging

- Blind shipping

- ~50-100m of additional fiber is needed for production (start/stop process)

- This cabling service is made on a ‘best effort’ basis, meaning that while it is rare, the possibility exists that customer supplied fiber can be damaged or destroyed during the cabling process (due to power outages / fluctuations or extrusion equipment issues)

- Precision OT/Opticonx cannot assume liability for the cost of damaged fiber

- Precision OT/Opticonx cannot replace customer supplied fiber if a manufacturing problem occurs

- If new fiber is supplied by customer, Precision OT/Opticonx will run the job again at no additional cost

- Historical failure rate is ~ 1%

Key Features

Applications

Documents

LOOKING FOR SOMETHING SPECIFIC?

Contact us to speak with one of our expert engineers.