Inspect Before you Connect: 4 Signs You May Have a Fiber Optic Connector Contamination

Fiber optic connectors play a crucial role throughout network architecture; they permit the capability to add, drop, move and change fiber optic cables throughout networks and data centers. Most commonly used in outside plant applications and throughout fiber installations, optical fiber connectors are mainly used to join fibers where a connect or disconnect capability is required.

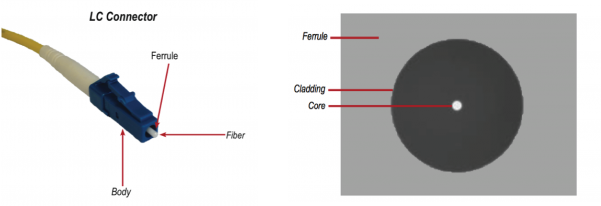

Fiber optic connectors are comprised of a body, ferrule, and fiber (which contains the cladding and the core). The diagrams below show the anatomy of an LC fiber optic connector at an overall view and through a probe microscope view:

Common Types of Connectors

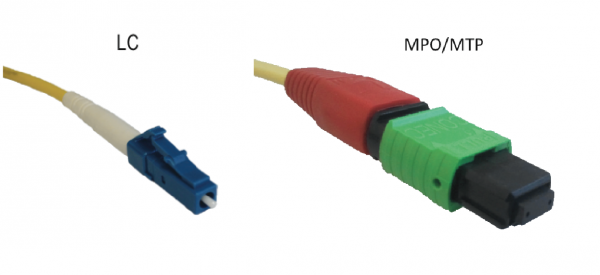

There are countless numbers of fiber optic connectors in existence; however, some are more prevalently used than others. The most commonly used types are the LC and MPO/MTP connectors.

The LC connectors are mainly used for high-density interconnections and have a unique click-in connection feature. The multi-fiber MPO/MTP connectors are also used for high-density interconnections; they are unique in the way that they support 100G applications and allow more fiber ports per unit of rack space. The MPO/MTP connectors are available in varieties from 12 to 24 fibers per unit.

Contamination

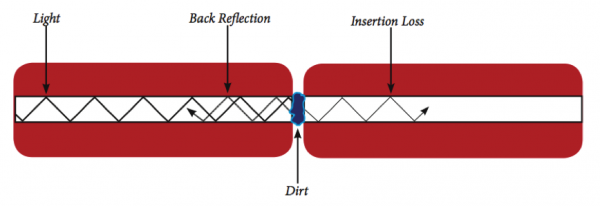

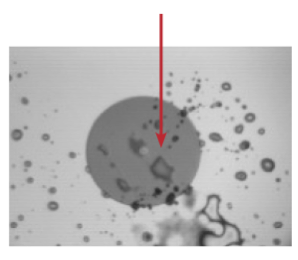

Transmission can be highly affected depending on the way the fibers are connected. When connected properly, light is transmitted successfully. When fibers are not connected properly or are contaminated, errors such as back reflection, insertion loss, and even equipment damage can occur.

The primary source of troubleshooting throughout optical networks is contamination; it is possible to occur through test equipment, dust caps, bulkheads, people, and the environment itself. If contaminated connectors are mated, debris are embedded into the fiber. When the connector is eventually cleaned, pits and chips remain from the debris.

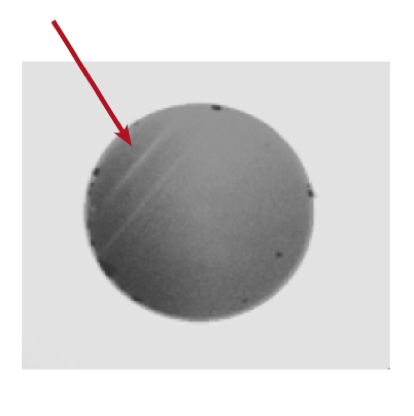

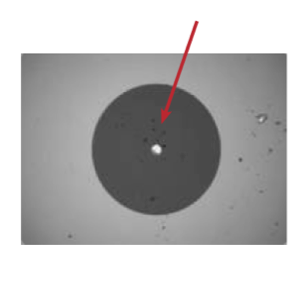

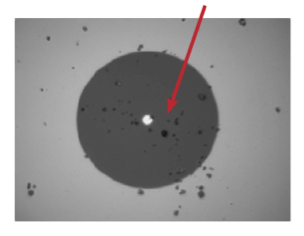

Contamination can occur in several forms. When using a probe microscope, look out for these red flags:

1. Scratches

2. Pits and Chips

3. Dirt (*Dirt is one of the most common types of contamination and is generally not visible to the human eye. Even a single spec of dust can result in defectiveness if embedded on or near the fiber core.)

4. Oil

Inspection/Cleaning Process:

Proactive inspection is the key to preventing contaminated connections. Be sure to:

1) Use a probe microscope to inspect fiber to check for any signs of contamination

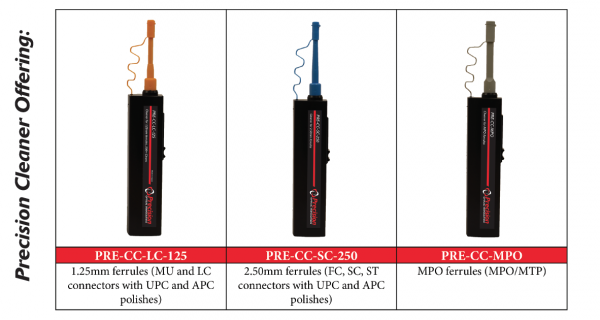

2) If dirty, use a simple cleaning tool to clean fiber surface, such as Precision’s click cleaner. Insert the cleaning guide into the device under cleaning. Once aligned properly, push the cleaner module forward until a clicking noise is heard, indicating that cleaning is complete.

3) Re-inspect using a probe microscope

4) If clean, connect. If dirty, repeat steps 2, 3, and 4

Be sure to inspect both the female (bulkhead) and male (patch cord) sides of the fiber interconnect. Inspecting proactively is essential to avoiding network troubleshooting due to contamination and can help prevent network damage.

Precision’s Click Cleaner Offering

Precision OT offers 3 click cleaner varieties that make for easy cleaning of transceivers, bulkhead adapters and/or fiber jumpers. The modules have a handheld design to make for easy-to-use cleaning and each contain 500+ cleans.

For additional information on fiber cleaning, cleaner modules or fiber jumpers, contact our experts here.