Into the Transceiver-Verse Part I: How to Choose the Right Transceivers for Your Network

There are hundreds of different types of optical transceivers! It’s no wonder selecting the right transceivers for your network applications may seem a daunting task. Broadband needs will continue to rise making it more important than ever to have an efficient network engineered with the right hardware for the job. According to OpenVault’s broadband study, by Q4 of 2021 the monthly weighted average data consumption per North American broadband subscriber was 536.3GB, surpassing over half a terabyte for the first time.

Fiber optic transceivers are essential in today’s networks and advanced developments in transceiver technology will continue to meet the data needs of the future. To aid in the task of choosing the right transceivers for your network, here are 6 key factors that should be reviewed with a transceiver/network system specialist before making your final selections. These technical and operational considerations will help determine the correct transceivers for any network application:

- Host compatibility

- Form Factor

- Distance/ Loss/ Link Budget

- Medium – (ie cable type)

- Fiber Connector Type

- Temperature Rating

Host compatibility

Before procuring transceivers, it’s imperative to know what kind of network equipment they will be used in and how the network is architected. What will the transceivers plug into? Determine how restrictive the host platform is to third party sources. Will you be locked into only OEM transceivers from the host or is it “friendly” toward other sources? For each switch, line card or whatever device your transceivers will plug into, you need to know the following at a minimum:

- manufacturer

- model #

- software version the host device is running

Uptime is critical, so it’s best to work with a trusted technical partner for all your networking needs including products, equipment, network knowledge and expertise.

Form Factor

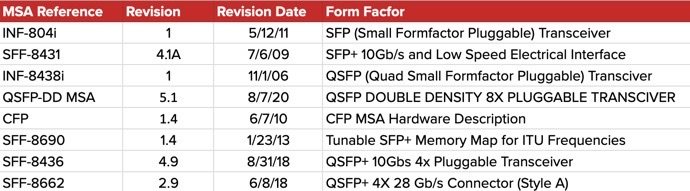

Not only do you need to know what type/brand of device the transceivers will plug into, but you also need some specific physical details about the transceiver ports. Ever wonder why transceivers are shaped the way they are? Several years ago, when optical transceivers became disaggregated from the switch and router, there were no industry standards. Seemingly, every company would have its own proprietary form factor. Eventually the primary industry players came together to create the Multi-Source Agreement (MSA) which helped define each transceiver product with specific electrical, optical and mechanical characteristics. Examples of actual MSAs are shown in the table below:

List of MSAs for Various Form Factors*

*For updates: Click Here

Features such as the metal casing size and shape of the transceiver became defined by the MSA. The development of MSAs resulted in the transceiver form factors we know and love today: SFP, SFP+, QSFP, QSFP+ and CFP to name a few. These small form factor interfaces plug into a switch or port which transforms the port into a fiber or copper interface. Understanding the functions and major differences between form factors is crucial when deciding the best fit for your optical network. Be sure to discuss the details with your transceiver technology partner.

Link Budget: How far does your data need to go?

The operating distances for optical transceivers can be as short as a few feet up to 2000km ( with coherent digital CFPs and other emerging transceiver technology). In some ways, the maximum distance rating should really be interpreted as a link budget. Link budget implies the amount of “usable light levels available”.

Link budget is the key criteria in determining which optic to use to properly establish a network physical link length. Typically in network design, a 2 dB to 3 dB link margin is required for any link budget. This requirement is to provide extra link margin in case the optical span should experience a level of degradation. The margin allows the link to handle the degradation without potentially impacting services. In effect, it means reducing the maximum RX(receiver) sensitivity by 2 dB to 3 dB which directly reduces the link budget by the same amount.

A simple link budget calculation would be the minimum optical output power minus the receiver sensitivity. However, as network systems increase in bandwidth requirements at longer distances, link budgeting needs to take into account issues such as chromatic dispersion and SNR (Signal to Noise Ratio). For example, upgrading from 1G to 10G presents difficulties with respect to signal spread and the simple link budget formula will no longer suffice. An 80km 10G SFP may have a link budget of 22dB which in theory should provide about a 100km reach using a loss of .22dB/ km. However, chromatic dispersion reduces the effective distance down to 80km. This penalty is even greater as you increase the data rate. A 25G signal will experience ~8x more chromatic dispersion than a 10G signal. It follows a cubic relationship. 25G is 2.5x the rate of 10G. (2.5)3 = ~8, therefore a 25G signal will only reach 10km vs 80km reached by the 10G signal. Chromatic dispersion is also wavelength dependent, but the data rate is the greatest determining factor. For a deeper understanding of chromatic dispersion and how to compensate for it in your link budget see “Chromatic Dispersion in 10Gb/s DWDM Systems”

Medium

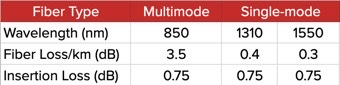

How does fiber material impact link loss? Just as transceivers have industry standards, fiber jumpers and fiber cables also have clearly defined industry standards. Different fiber cable types have different fiber loss at their working wavelengths as shown in the TIA-568-C.0- 2 standards shown below. This table provides a good loss approximation, but in practice the true loss of a link should always be measured at the operating wavelength with an OTDR (Optical Time Domain Reflectometer) trace.

Maximum loss values of multimode fiber and single-mode fiber

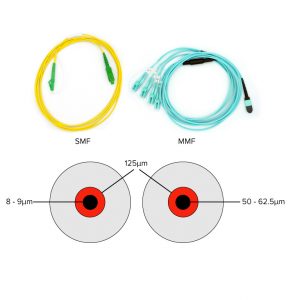

Two main fiber types are important to keep in mind when pairing with a transceiver; single mode and multi mode. Multimode is less expensive to manufacture but at the cost of higher attenuation and greater refractive indices relative to single mode fiber. Single mode fibers are used for high speed data transmission over long distances as they are less susceptible to attenuation than multimode fibers.

Fiber Connector Types

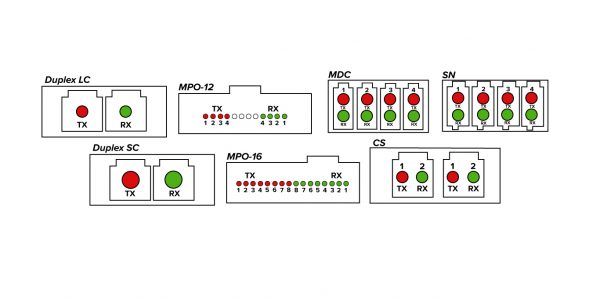

Below are some available transceiver optical port connector types:

The SC fiber connector is somewhat of a predecessor to the LC connector, as the two share the same basic design. The difference between the two is the SC ferrule is roughly double that of the LC. Duplex LC and SC as shown above are fairly straightforward: one side is your Tx, the other side is your Rx. MPO-12 and MPO-16 get a little more complicated. The 12 and the 16 imply the number of fibers contained inside the cable. “12” in MPO-12 indicates 12 fibers, however it is only utilizing 8 lanes. SN is a newer type of fiber connector designed and optimized for 400G applications. It is basically 4x dual LCs compacted into a connector. It enables 4 duplex lanes from a 400G transceiver. The MDC connector is also a newer variety and largely used for 400G.

As far as fiber endface polish types there is UPC (Ultra Physical Contact) or APC (Angle Physical Contact). UPC fiber endfaces are “flat” while APC fiber endfaces are polished at an eight-degree angle. APC gives better optical return loss which gives a slightly better link budget than UPC. However there are situations where UPC, the slightly less expensive choice, may be good enough in terms of optical performance. Whichever polish type is chosen for your application, keep in mind that APC and UPC cannot be mated together.

Temperature Rating

In what type of environment will your transceiver be utilized? Is it going to be in a data center that is temperature controlled, or is it being plugged into a node out in the field in Houston, Texas where it can hit >100ᣞ in the summertime? You should be able to get just about any transceiver type in either industrial temp or commercial temp ratings. Generally the specified temperature ranges for transceivers are as shown below. However these may vary slightly depending on the manufacturer.

- Commercial Temperature Range: 0 °C to 70°C

- Industrial Temperature Range: -40°C to 85°C

- Extended Temperature Range: varies by manufacturer

Before ordering be sure to ask whether your transceiver will go through rigorous environmental testing cycles in an engineering lab, both from a hardware and system level perspective.

Now you know what questions to ask in determining which transceivers to use for your applications. The next question is, who will you have that conversation with?

How to choose the right partner for transceivers

With network operators under pressure to deliver higher speeds and bandwidth across backbone, metro and access networks, the need for a reliable optical network equipment provider has only increased. How can you be certain that the company you rely on for transceivers and other optical equipment is more than just another vendor? How can you trust that they will have your back in tricky or complex situations? The answer lies in looking for the following three qualities in your optical network equipment provider:

- Reliable Inventory

- Engineering Support

- Custom Solutions

Most importantly, pick a provider that is more than just an equipment manufacturer. Full lifecycle support, laboratory testing and expertise in all types of network architectures can ensure you get the most out of your spending. You need expert engineers on hand, not just sales reps.

Precision OT is an integration engineering firm providing custom solutions for optical networking equipment. We have a team of dedicated systems engineers and an R&D department focused on developing next generation fiber optic transceivers. Precision OT’s business model is to provide Tier 1 quality hardware matched with the industry’s best system engineering support.

In addition, Precision OT collaborates with customers to better understand their operational and inventory needs. With effective communication and relationship building, we can ensure we stock the right inventory by better understanding customers’ short and long-term network strategies. To mitigate risk, we have strong relationships with multiple and diverse suppliers. During the pandemic, when there have been shortages with products such as SPF100G(LR4, SR4 and ZR4), 10G Tunable SFPs and copper SFPs, Precision OT is able to supply these based on planning done a year or more in advance. Precision is a privately owned company, not susceptible to some of the operational challenges experienced by companies owned by private equity firms.

There are many different types of transceivers with various form factors, data rates, link budgets and transmit technology types. All of these were developed to cost optimize a specific application or solution. In the end, the right transceiver comes from the right partner. Transceiver experts, such as Precision OT, will take the information gathered from the above 6 considerations and provide high quality, custom-engineered, OEM-compatible transceivers that will perform reliably in your network.

Like what you’re reading? Check out part 2 of our Into the Transceiver-Verse series, where we dive into the various transceiver types available and the technologies behind them!