APC and UPC: What Can Polish Do For You?

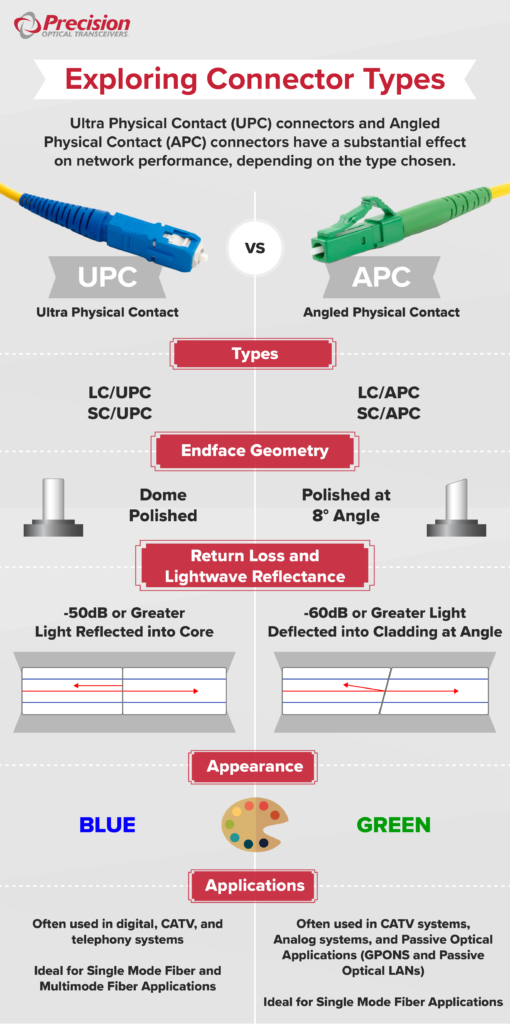

Angled Physical Contact (APC) and Ultra Physical Contact (UPC) connectors have both become commonplace in modern fiber optic network designs, but they each work best in specific use cases. While both can be used for single fiber applications, APC connectors provide much higher performance capabilities in certain types of networks. In this blog, we dive into the background on APC and UPC connectors to give you a helpful way to avoid costly issues with your network design and function.

A Little Context

Before we get into the nitty gritty of APC and UPC characteristics (hint: it’s in the polish), it’s worth remembering that both stem from initial work around Physical Contact (PC) connectors. Basically, PC connectors were designed with ferrules polished into a spherical cone design. This design reduced the size of the connector’s end-face, decreasing the air gap that was typically left when mating two regular flat fiber connectors. As a result, PC connectors helped network operators lower overall loss as well as Optical Return Loss (ORL), which is a measurement of the amount of light that gets reflected back to the power source. For PC, ORL is roughly -40dB; for reference, a value of -1dB would indicate an extremely poor connection.

UPC and APC: Characteristics and Use Cases

UPC connectors take this one step further with an extended polishing technique that refines the surface from a flat mating to an angled one, thereby reducing ORL significantly to -56dB or less. As a result, this design has become popular for high power single and multimode fiber applications where optical interference from back reflections is unacceptable. UPC connectors are thus required for standard digital SFP optical transceivers, which have flat connectors. Though they are robust with minimal insertion loss, the ORL of UPC connectors will nevertheless degrade over time with repeated matings.

As service providers look to adapt their network designs to meet the bandwidth demands of end-users, the standard UPC connector is giving way to APC models in certain instances. A growing number of operators are now involved with applications like HD video streaming, which are sensitive to return loss because they use optical transmitters that are very sensitive to reflected light. Additionally, FTTX and PON networks that run upstream and downstream as well as video wavelengths on a shared single fiber network also require the lowest ORL possible to maintain data integrity. As a result, APC connectors are a choice product for high-performance, analog (video), passive optical LAN, FTTx, and CATV networks.

Demand for APC connectors will likely rise as network operators invest further in WDM applications with stringent return loss requirements.

What’s the Net-Net?

The bottom line is this. Both UPC and APC connectors are the product of the optical networking industry’s unending need to diminish ORL and improve the resilience of signals being sent through optical fiber. We cannot say that one type of connector is better than another. What we can say, though, is that the use of a connector is, in many ways, governed by use of other optical equipment.

For example, it is not possible to use APC connectors with SFP optical transceivers. Likewise, it is impossible to mate a UPC connector with an APC one. Nevertheless, connectors do play a significant role in influencing what kind of return losses your network will face – so keep that in mind!

Did you find this infographic helpful? Do you have questions that need answering? Contact us!